Q: Why is arsenic found in groundwater and why is it difficult to remove?

A: While arsenic is found naturally in rocks and soil and is released into water supplies through erosion, some industrial practices also have the potential for releasing arsenic into the environment. Arsenic can be discharged into groundwater as a by-product of the industrial treatment process during the production of paints and dyes, metals, soaps, drugs, and wood preservatives. Arsenic can be difficult to remove because it is soluble and dissolved in water.

Q: What kinds of health risks are associated with arsenic consumption?

A*: Inorganic arsenic compounds such as those found in water are highly toxic. Symptoms of acute arsenic poisoning include vomiting, abdominal pain and diarrhea. These are followed by numbness and tingling of the extremities, muscle cramping and death, in extreme cases.

The International Agency for Research on Cancer (IARC) has classified arsenic and arsenic compounds as carcinogenic to humans, and has also stated that arsenic in drinking-water is carcinogenic to humans.

Long-term effects of ingestion of inorganic arsenic include developmental effects, neurotoxicity, diabetes, pulmonary disease and cardiovascular disease. Arsenic is also associated with adverse pregnancy outcomes and infant mortality, with impacts on child health, and there is some evidence of negative impacts on cognitive development.

* from World Health Organization)

Q: Why is adsorption an excellent technology for removing arsenic?

A: There are various options for removing arsenic, including ion exchange, activated alumina, reverse osmosis, coagulation/filtration, and adsorption.

While coagulation/filtration can prove to be an effective solution when treating for high levels of multiple contaminants, it does have higher initial capital costs and is more labor intensive. It is more complex than adsorption, which can be a key concern for utilities without centralized treatment plants.

Adsorption, on the other hand, is a simple, passive process, with a relatively low cost. One of the advantages of iron adsorption is the predictability of the breakthrough. Comparatively infrequent monitoring of performance can give optimum performance and both arsenate and arsenite are removed.

Q: How does the De Nora SORB 33 arsenic removal system work?

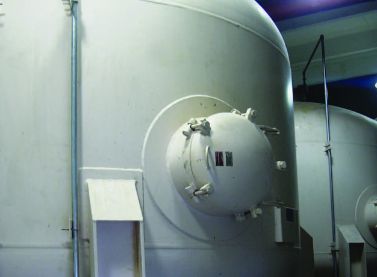

A: The De Nora SORB 33 arsenic removal system is a fixed bed adsorption system that uses a granular ferric oxide media, Bayoxide E33® *, for the adsorption of dissolved arsenic. The system employs a simple “pump and treat” process that flows pressurized well or spring water through a fixed bed pressure vessel containing the media where the arsenic removal occurs. Both arsenite (arsenic III) and arsenate (arsenic V) oxyanions are removed from water via a combination of oxidation, adsorption, occlusion (adhesion) or solid-solution formation by reaction with ferric oxide ions.

Q: Can the granular ferric oxide media be optimized for longer life?

A: Media life typically ranges from 6 months to 6 years, depending on water quality levels. Media usage can be optimized in multiple parallel flow adsorber systems via staging. The media life cycle for each adsorber is staggered such that one is operating in the latter stages of its life while others are operating at earlier stages of media life. The adsorber with the oldest media can operate to 12-14 ppb arsenic breakthrough because its water is blended with other adsorbers discharging water with arsenic in the 2-6 ppb range. The treated water from the adsorbers contains an arsenic level of about 8 ppb.

Although systems are usually simple to operate, owners may consider the additional backup of service agreements to support the most effective operation of the system to extend media life and undertake media change-out when required.

Q: What does De Nora’s media replacement service include?

A: When an operation’s arsenic removal media is approaching exhaustion, the operator, with assistance from a De Nora subcontractor, sends a sample of the media to De Nora’s certified laboratory for the EPA’s TCLP metals (or CA’s STLC metals) analysis. Once analyzed, the media can be scheduled for replacement. On the day prior to replacement, the operator drains the adsorber(s) of water prior to initiating the media change out (MCO). The subcontractor transfers the spent media into trucks or sacks for disposal. The site is cleaned and the equipment is ready to be placed back into service, and the contractor hauls the spent media to a disposal site, securing all of the proper paperwork.

Q: Besides media replacement and disposal, what can the client expect from this service?

A: De Nora’s process oversight of the MCO ensures that the operation is conducted properly with close attention to detail. A De Nora process engineer oversees the operation, inspecting the interior of the vessel and monitoring the new media chlorination and backwashing after media installation. The engineer also assesses the past performance of the media based upon the volume treated, then compares that it with original performance expectations. With an updated comprehensive water analysis from the client for the assays listed in De Nora’s site qualification form, the overseeing engineer can determine if any adjustments to the bed volumes (or million gals) should be made. In addition, he or she determines if any internal lining coating repairs need to be made and checks the system’s instruments for operability and reliability. The engineer reviews the current mode of operation with the client, identifies any ongoing problems, and makes recommendations for improvement. A few weeks after completion, an MCO report on the service is issued to the client, which includes the status of the spent media disposal.

* Bayoxide® is the registered trademark of Bayer AG and used by Lanxess Corporation under license from Bayer AG