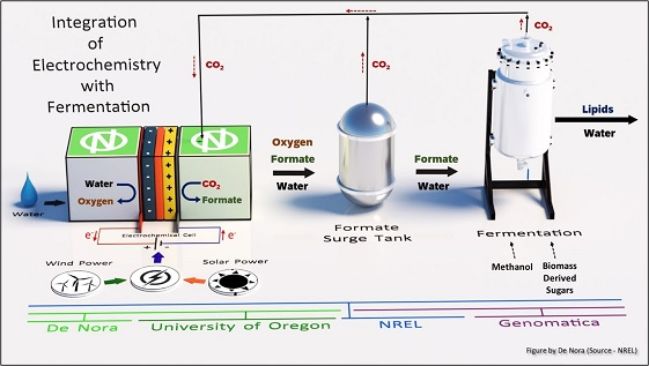

Integration of Electrochemistry with Fermentation*

De Nora is excited to announce that it will be part of a $3 million program funded by the U.S. Department of Energy’s Advanced Research Projects Agency-Energy (ARPA-E) under the ECOSynBio program to develop a sustainable carbon dioxide (CO2)-emissions-free biofuel technology. The team of scientists at De Nora, NREL, and the University of Oregon will integrate their electrochemical expertise with Genomatica’s and NREL’s sugar fermentation expertise to produce fatty acid methyl esters (FAME), lipids used to make biofuels.

During the current fermentation process to convert sugars from biomass feedstocks to make renewable liquid fuels, approximately one-third of the carbon in sugar is lost as CO2. To fully utilize the carbon from these precious biomass sources and thus reduce the overall environmental footprint of the process, the team will develop a CO2 recycling and conversion system that allows for reduced or no net CO2 emissions from the fermentor by electrochemically upgrading the waste CO2 into formate which is then utilized by the fermentation process to produce more FAME.

De Nora is a global leader in industrial electrochemistry committed to investment in sustainable decarbonization technologies including green hydrogen production and electrochemical carbon dioxide conversion technologies. De Nora will leverage its long history of designing, developing, and supplying Gas Diffusion Electrodes (GDEs), Gas Diffusion Layers (GDLs), catalysts, and related cell technologies for electrochemical applications and on-going R&D efforts in CO2 conversion to develop the scalable electrochemical system for the conversion of CO2 to formate at the heart of this process.

Ultimately, the proposed integrated effort will help reach a critical milestone for meeting biofuel demand. While U.S. renewable diesel production has projected to expand from 0.4 to 4 billion gallons per year by 2024, U.S. airlines also favor sustainable aviation fuels (SAFs) to mitigate aviation greenhouse gas emissions. Therefore, proposed technology will not only meet the increased SAFs demand, but also alleviate the fuel’s carbon intensities while demonstrating the endless possibilities of electrochemistry to decarbonize similar refining processes.

For more info,

https://arpa-e.energy.gov/news-and-media/press-releases/us-department-energy-invests-35-million-dramatically-reduce-carbon

* This biorefining concept uses electrochemically generated formate as a universal energy carrier to facilitate a carbon optimized sugar assimilation fermentation to synthesize fatty acid methyl esters (FAME) without the release of CO2