Following the acquisition of MIOX Corporation by De Nora and the integration of ClorTec with MIOX, De Nora now offers on-site chemical generators for mixed oxidant solution. What exactly is mixed oxidant and how does it different from sodium hypochlorite? Tom Muilenberg, Vertical Market Manager for De Nora, answers these questions and more.

What is mixed oxidant solution?

The main component of mixed oxidant solution (MOS) is chlorine and its derivatives hypochlorite and hypochlorous acid (ClO−, HClO). It also contains trace amounts of other chlor-oxygen species which work synergistically with the hypochlorite/hypochlorous acid to improve efficacy and performance. MOS is made from brine (salt) and energy, and is used for disinfecting, sanitizing and reducing the risk of infection due to pathogenic microorganisms in water and in other applications. It is particularly useful for customers who have specific challenges such as controlling biofilm or reducing disinfection byproducts exacerbated by biofilms.

How is MOS made?

Mixed oxidant solution is produced by electrochlorination. Sodium chloride (NaCl) brine is streamed through a channel with a cathode and an anode. When a low voltage current is applied in the cell, sodium hypochlorite and hydrogen gas are produced. The hydrogen is removed, and the mixed oxidant solution is stored in a tank and used as needed. The only chemical required to generate MOS is ordinary salt (NaCl). The same process is also used to generate standard sodium hypochlorite. Although the chemical processes involved are complex, they are represented simply as:

NaCl + H2O + ENERGY → NaOCl + H2. In short, energy is added to sodium chloride (table salt) in water, resulting in sodium hypochlorite and hydrogen gas.

How is generating MOS different from generating standard sodium hypochlorite?

Both MOS and sodium hypochlorite are generated on-site, on demand using the process of electrolysis. In fact, from the outside, there’s no discernable difference in the equipment. However, for advanced disinfection needs, the cell in the mixed oxidant generators are optimized for challenging applications. Basically, more power is applied to the solution, which is achieved via design modifications to the cell and operating conditions.

If the generation process is the same, what’s the difference between sodium hypochlorite and MOS?

Chlorine-based mixed oxidant solution has all the oxidant power of sodium hypochlorite with additional treatment benefits including biofilm removal, disinfection byproduct (DBP) reduction, improved taste and odor, and improved water clarification. With mixed oxidant solution, customers maintain more consistent control and residuals with a lower dose.

What is MOS used for?

Mixed oxidant solution can be used for a variety of water treatment applications, including:

- Cooling water treatment

- Industrial process water and wastewater treatment

- Cooling tower water treatment

- Aquatics (swimming pool disinfection)

- Drinking water & beverage facilities

- Municipal wastewater

- Farm applications

- Oil & gas water management

How does the efficacy of MOS compare to standard delivered bulk sodium hypochlorite?

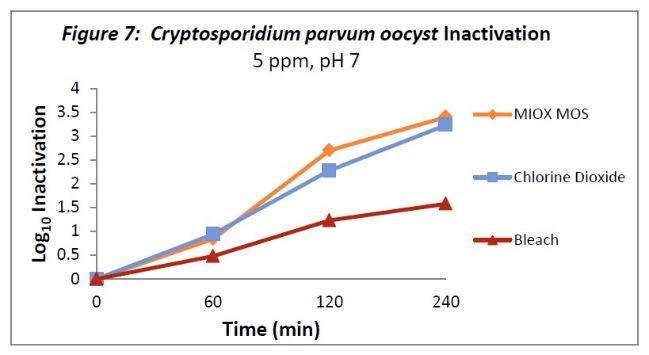

Several peer-reviewed publications have published articles demonstrating the superior efficacy of MOS compared to sodium hypochlorite. MOS benefits were proven via extensive comparative studies using four microorganisms, two different temperatures and three different pH values. The microorganism tested were Escherichia coli, Vibrio cholera, Clostridium perfringens spore and MS2. For each of these conditions, MOS performed better, even at low temperature and higher pH than chlorine. Years of compiled field data also show differences in the efficacy of MOS.