New and more stringent regulations require removal of additional micropollutants and emerging contaminants. Finding the best technology to accomplish these goals can be difficult.

De Nora is a global company with over 50 years of experience providing reliable, effective, and innovative products for the water industry. Alex Bettinardi discusses how ozonation can combat micropollutants and aid disinfection.

How does the ozonation process work?

Ozone is a pale blue gas composed of three oxygen atoms (O3). Ozonation is a water treatment method where ozone is generated on-site and introduced into water to eliminate a wide range of organic compounds and microorganisms. The transformation of oxygen into ozone, a very powerful oxidant, occurs with the use of energy. Inside the ozone generator vessel, ozone is produced from oxygen present in the feed gas by means of a silent electric discharge (non- thermal plasma). Ozone is dissolved into the water. It produces a direct oxidation reaction on the pollutants/molecules.

What are some of the applications for ozonation at water treatment plants?

Ozone is used as a stand-alone technology in some cases. It can also be combined with hydrogen peroxide (H2O2), ultraviolet light, or active chlorine to perform an advanced oxidation process (AOP). This AOP produces highly reactive hydroxyl radicals (·OH). These reactive species are the strongest oxidants that can be applied in water. They are used to address contaminants with high chemical oxygen demand (COD) or non-biodegradable molecules. They also improve the overall quality of the water.

Ozonation can be used to complement chlorine disinfection of drinking water. By using ozone, utilities can limit or avoid the use of chlorine if there’s a concern about dangerous byproduct formation. Ozone also treats groundwater that has been polluted by metals, like iron and manganese, and inorganics, such as hydrogen sulfide (H2S), that are easily oxidated by O3.

What do you know about the threat posed by micropollutants? Do many treatment operations consider them to be a concern?

Endocrine disrupting compounds (EDCs) are chemicals that, at certain doses, can interfere with endocrine systems. These disruptions can cause cancerous tumors, birth defects, and other developmental disorders. Drugs and pharmaceutical residuals are not effectively treated with the traditional wastewater treatment plants.

Switzerland is the first country that has enacted a specific law, but many countries are conscious about this serious concern.

Some countries, like Germany and France, are addressing the micropollutant issue even faster than Switzerland, despite a lack of regulation.

Why is ozonation a good solution for micropollutants in wastewater? How does it work to eliminate them in particular?

Ozone is among the most powerful known oxidizing agents and has one of the highest redox potentials. The formation of byproducts is very low and sometimes absent. Stand-alone ozone effectively treats non-biodegradable products, including micropollutants substantially untreated through the conventional activated sludge process.

What other solutions are available for combating micropollutants? Why might ozonation be a better option?

There are several technologies available to remove micropollutants, including reverse osmosis membranes. However, granular activated carbon (GAC) is the most convenient and simple technology for this application. GAC is typically used in combination with ozone because GAC alone is not always enough. The advantage of ozonation is related to the direct oxidation of micropollutants. Ozonation transforms micropollutants into more biodegradable compounds that are easily adsorbed and decomposed on the downstream filter, commonly called the biological activated filter.

Would you say that ozonation is the best technology for combating micropollutants?

In most cases, GAC alone is not enough to protect the population from EDCs’ risks. Ozonation is surely one of most effective and convenient treatment options available when used in combination with other technologies. Technologies often paired with ozonation include GAC and biological filtration, which uses a different filter media.

What can you tell me about CAPITAL CONTROLS® ozone disinfection solutions? How long has that been part of De Nora’s portfolio? What does that offer in terms of ozone solutions?

Founded in 1970, Italian-based Ozono Elettronica Internazionale (OEI) offered ozonation disinfection solutions to municipal drinking and wastewater treatment markets, the pharmaceutical and food industries, and agribusiness. The technology was acquired by De Nora in May 2015 to complement De Nora’s existing line of products. DNO now has a special focus on developing and extending its reach into the water and agrifood sectors.

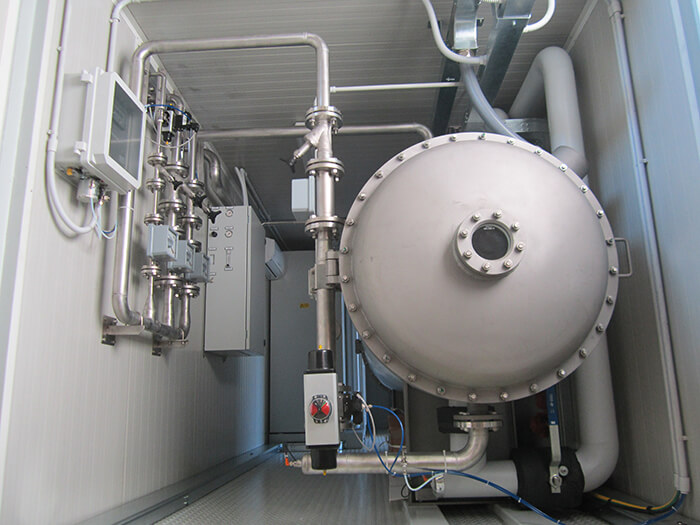

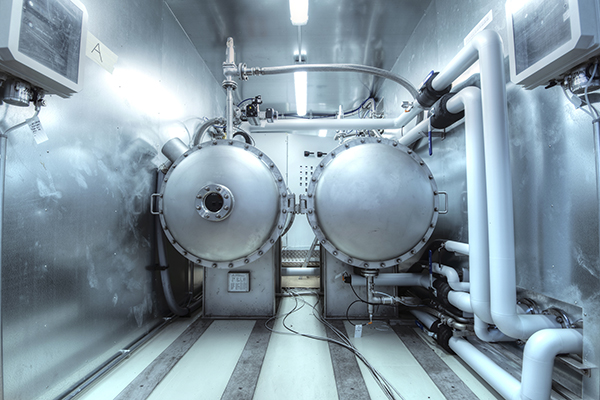

With more than 1,200 worldwide installations, CAPITAL CONTROLS® technologies range from 40 g/hour to 100 Kg/hour ozone production. Stand-alone modular units or customized systems are available for the entire process: gas feed preparation, ozone generation, contact systems, ozone destroyers, instrumentation and controls, and packaged or containerized units